The stepper motor and the servo motor are the same in control mode. It is an application of digital control technology.

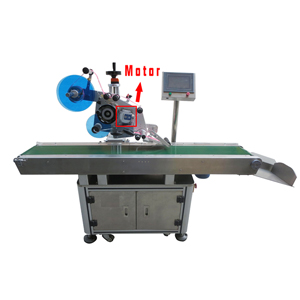

Labeling machine motor position

The stepper motor is suitable for ordinary labeling machines. Stepper motors can be used with low speed and accuracy requirements. If the labeling speed is high, the label is small, or the object is small, it is better to use servo control.

However, the cost of servo motors is higher than the cost of stepper motors. Whether to choose stepping or servo, it depends on the customer's requirements.

Main difference between stepper motor and servo motor

Stepper Motors | Servo Motor | |

Speed response performance | Startup takes 150-400 milliseconds | Startup takes a few milliseconds |

Control precision | Low | High |

At low frequency | There will be vibration | Normal operation |

Moment frequency characteristics | The output torque decreases as the speed increases. The highest speed is between 300RPM and 600RPM. | Constant torque output. |

Overload capability | No overload protection | Strong overload protection |

Operating performance | Open-loop control, if the starting frequency is too high or the load is too large, it is easy to be disordered. So it is necessary to deal with the problem of speed increase and speed reduction. | Closed loop control, the drive directly samples the motor encoder, so the control performance is more reliable. |

If you don't fully understand the difference between the motors, or have questions about other parts of the labeler.

Contact us, we will give you a professional answer.

Copyright 2018 ©ZHUONUO WINSKYS TECH CO.,LTD All rights reserved.